UG Cables - Underground Cables: Basics of Insulation & the Structure

Let’s see, basics of Insulation and the structure of Underground Electrical power cables. We know, that the Electrical power cable is a crucial part of the power system. In simple words, it is an alternative to overhead power transmission lines. The laying of electrical power cables is done underground. Hence, it is used in areas where overhead transmission lines are impractical, such as densely populated urban areas, airfield passages, and the sea. One of the major challenges, in the use of underground cables, is its high capital cost.

Mainly, there are two types of electrical power cables. One is an oil-filled power cable, and the other is a solid insulation power cable.

Based on the number of cores there are single-core cables and multicore cables.

Also based on the types of the core there are solid core cables and stranded core cables.

As we know, the cross-section size & type of the core is decided by the magnitude of current it carries. Similarly, the insulation of the cable is decided by the voltage level of the cable.

Now, for example, let’s see a 220 Kilovolt cable. We can see an imprint on the cable. As per the imprint, 127KV is the phase voltage and 220KV is the line voltage of the cable. 1C signifies, that it is a single core cable. 1000 square mm is the cross-section area of the stranded core. 1C X 1000 square mm signifies that this is a single core cable with a 1000 square mm cross-section area. 2018 is the manufacturing year of the cable. Hence from this imprint, we understand that it is a 220KV, single-core cable with a 1000 square mm core size.

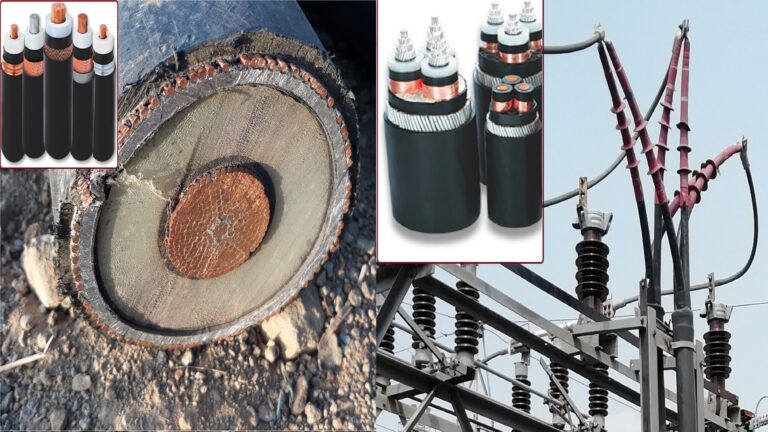

Now, let’s see the cross-section area of the same cable. We can see the core of the cable that is stranded copper conductors, with a collective cross-section area of 1000 square mm, as mentioned on the cable. Conductor screening covers these stranded conductors.

After that, there is a thick layer of insulation, XLPE i.e. cross-linked polyethylene insulation. Insulation material can be paper insulation, PVC i.e. Polyvinyl Chloride, or PE i.e. Polyethylene. In this case, insulation is XLPE.

We can see a layer of the aluminum sheath covering the insulation. It is used to hold these multiple conductors inside the cable together.

A thin layer of bedding can be seen in between sheath and armoring. It is made of fibrous materials like jute or hessian tape. Bedding is done to protect the sheath from mechanical injury due to armoring. Also, it acts as a shock absorber.

Over the bedding, there is a layer of armoring, done using copper strands. armoring is provided to protect the cable from mechanical injury during the handling and lying of the cable. Due to armoring the cable can withstand higher stresses and can be buried directly underground. The armoring is usually connected to the earth.

And finally, there is the outermost PVC insulation sheath layer. It is also called serving.