SF6 Circuit Breaker - Arc quenching inside Interrupter

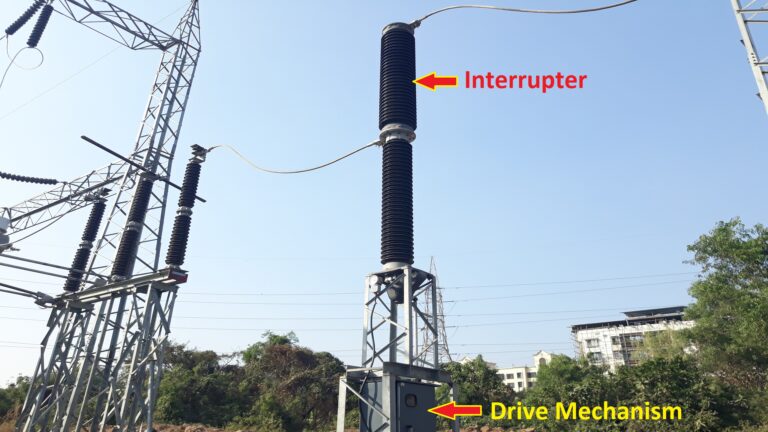

Generally, 145 K V and above ratings circuit breakers are SF6 circuit breakers. In the picture below is a 220KV SF6 circuit breaker, and this is the single pole of the circuit breaker. These are top and bottom connection palms, where conductors are connected. This is an SF6 gas pressure gauge, to monitor SF6 gas pressure inside the interrupter. As we know any circuit breaker has two main components.

1. Interrupter: Where close and open operation of contacts takes place.

2. Drive mechanism.

First, let’s see what is inside this Interrupter.

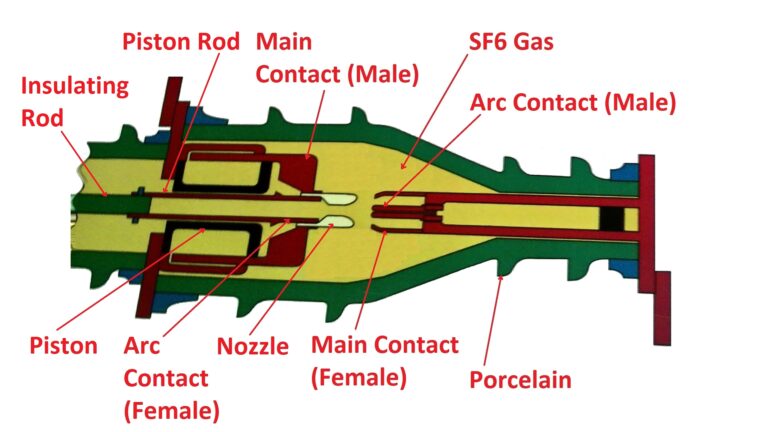

Here in the diagram, we can see a longitudinal section of the interrupter. This is an airtight chamber filled with SF6 gas, inside porcelain housing. We can see two main contacts, this one is male contact that is moving, and this other one is female contact that is fixed. This is what these two contacts look like. If we look closely, we can see there are two more contacts, relatively smaller. These contacts are called arc contacts. This one is male arc contact which is fixed, and this other one is female arc contact which is moving. This is a nozzle that is made of non-metallic insulating material. The function of the nozzle is to direct SF6 flow towards arcing region, to accelerate arc quenching. These are pistons and this is a piston rod. Pistons are used to push SF6, to blow it on the arc, for effective arc quenching. The piston rod is coupled with the insulating rod. This is what the insulating rod looks like, which runs through this stack and drives the piston rod, and subsequently moving contacts during operation.

So let’s see how close & open operation happens inside the interrupter.

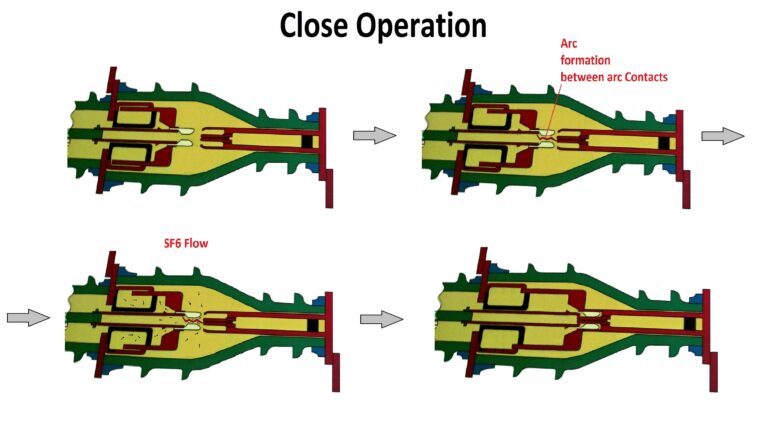

This is open condition. Once the close command is given to the circuit breaker, moving contacts move towards fixed contacts. Just before closing arc is formed between arcing contacts because the distance between arc contacts is less than the distance between main contacts, arc contacts being more in length. During this operation, SF6 gas gets accumulated in the region between pistons and the main contact. Finally, the arc and main contacts get closed, and the arc is quenched. This is how close operation takes place inside the interrupter.

Now let’s see the open operation.

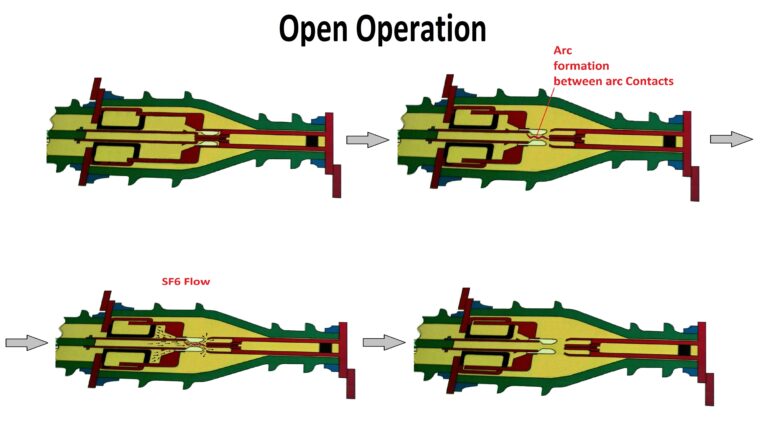

This is a closed condition. Once the trip or open command is given to the circuit breaker, moving contacts move away from the fixed contact. Firstly, main contacts open, and then arc contacts open. Hence arc is produced between arc contacts. During this time SF6 accumulated between main contacts and pistons gets compressed due to contact movement and is pushed into the arc region, through the nozzle. Hence arc is successfully quenched. This is how the open operation takes place inside the interrupter.

Please note that arcing phenomenon is more critical and persistent during open operation than during close operation. That’s why interrupter is designed mainly to quench arc formation in open operation. How? Let’s see.

Because in close operation contacts move towards each other, and a solid conduction path is provided for current once contacts are closed. Hence arc doesn’t persist once contacts close. But in open operation, contacts move away from each other. Arc is formed and it gets elongated as contacts move away from each other. This phenomenon persists longer. Also, early interruption of arc in open operation minimizes the break time of fault current. Hence interrupter is designed mainly to quench arc in open operation.

Why do we use SF6 as an arc quenching medium? How does it help to quench the arc?

Let’s see the properties of SF6 gas.

SF6 is chemically stable at high temperatures, even at 500 °C.

It is non-toxic and non-inflammable.

It has excellent dielectric properties, hence it is an outstanding arc quenching medium.

So because of these properties, SF6 gas is used as an arc quenching medium.

Now, let’s see the function and composition of arc contacts. The function of arc contacts is to contain arc, hence they assist in arc quenching. For that purpose, these arc contacts need to have high resistance as compared to that of main contacts. Also since arcing is associated mainly with arc contacts, these contacts heat up more, as compared to main contacts. So to limit arcing phenomena and to withstand high temperatures, these arcing contacts are coated with tungsten material. Tungsten metal has both required properties. It has high resistance hence it assists in arc quenching, and can withstand high temperatures.